When it comes to storage, one thing commonly found in a facility is pallet racking. This is a staple of many storage operations as it makes use of vertical space, provides employees easy access to inventory, and offers proper space for materials and products.

However, a racking solution usually consists of just beams and uprights with large gaps in between. Therefore, a racking solution is often accompanied by wire decking!

Nashville Wire, a manufacturer of wire decking and other wire products, offers high-quality wire decking options to fit a variety of different racking solutions. This allows you to create different custom designs in order to adhere to specific processes, product organizations, and safety measures.

Understanding Your Needs

So here you are, a facility manager with a newly implemented racking solution and a need for wire decking to complete the project. What do you purchase? Here are some questions you should be thinking of before choosing decking options:

- What products/materials am I trying to store?

- Are there any safety measures I need to look out for?

- How will these products/materials get picked?

- Do I have a lot of different items in need to properly organize?

Once you have answered these questions you should have a pretty good idea of your storage process and what you are looking for, however there are many ways to set up wire decking that offer increased safety, organization, and security.

We worked with Nashville Wire to find out some creative ways to set up wire on your racking solution!

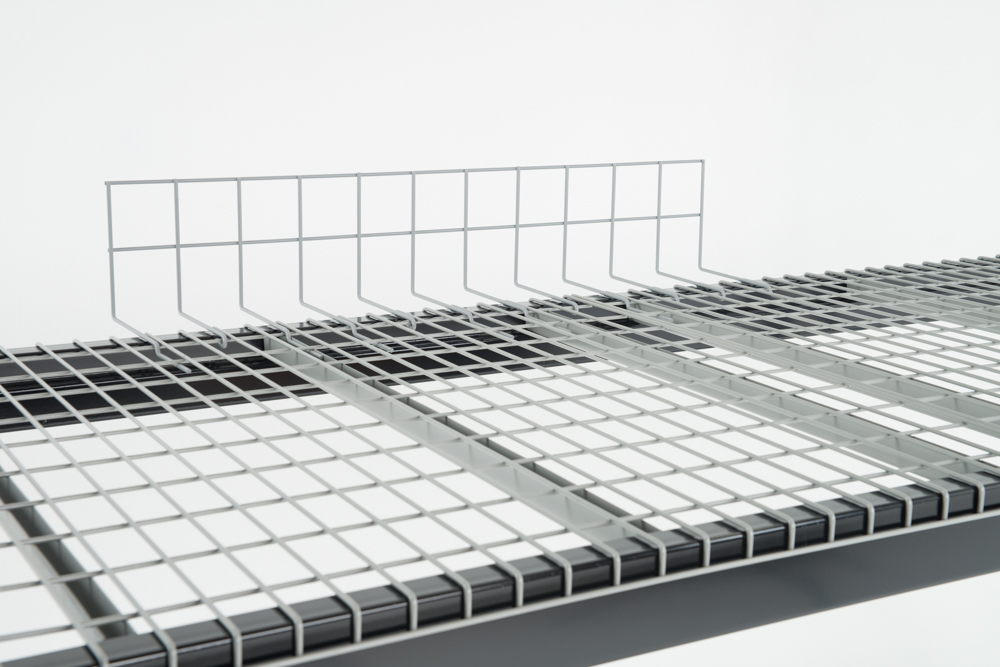

Retrofitting Backstops

The first creative method to creating a wire decking solution is retrofitting backstops. Backstops are great for keeping inventory secure by not allowing items to fall from the back of the rack as they are pushed back to create room for more inventory.

Nashville Wire’s Kwik-Stop™ allows for this security on the back of the racking solution and can attach to any existing or new Nashville Wire deck that is 46” wide. Kwik-Stop™ can be installed flush or be extended should there be a need to add space for more items.

Retrofitting backstops to your decking solution is also great for the safety of your workers as items will not fall from a high level and injure employees walking below!

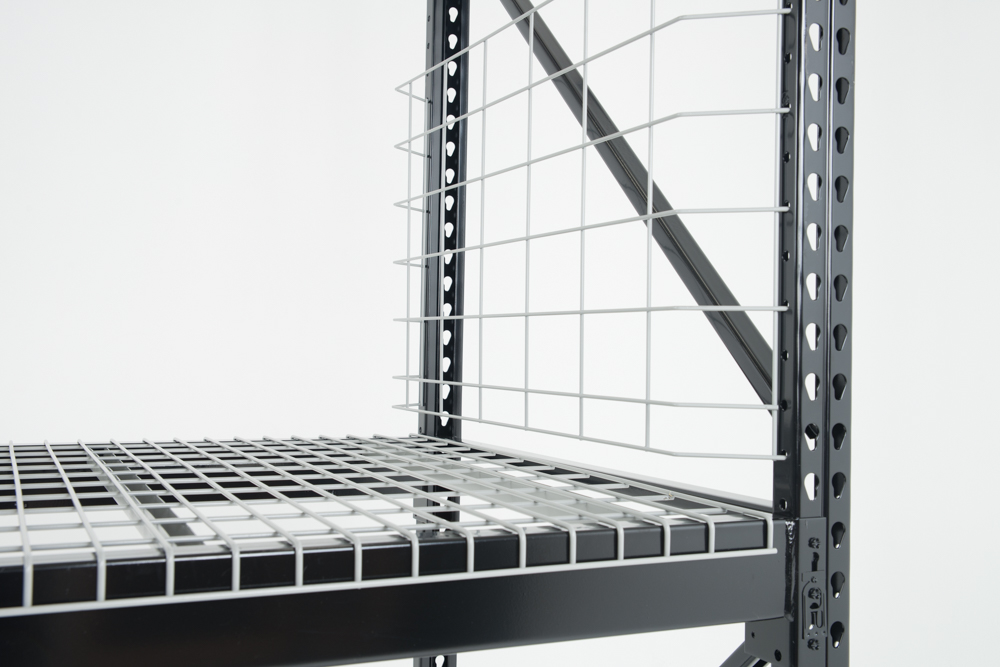

Creating End Flues

Fire marshals have begun to require a 3” flue by the upright in rack systems in order to maintain a high level of safety and eliminate fire hazards within the facility.

An end flue creates a buffer on the side of the racking solution keeping inventory separated from the edge of the racking solution.

Nashville Wire has developed a divider that fits in the holes of the upright to provide proper flue requirements. This divider stays consistent with wire decking on the racking solution to create a sleek and uniform look! They also allow you to adhere to the 3” standards and create a safe environment on your racking solution.

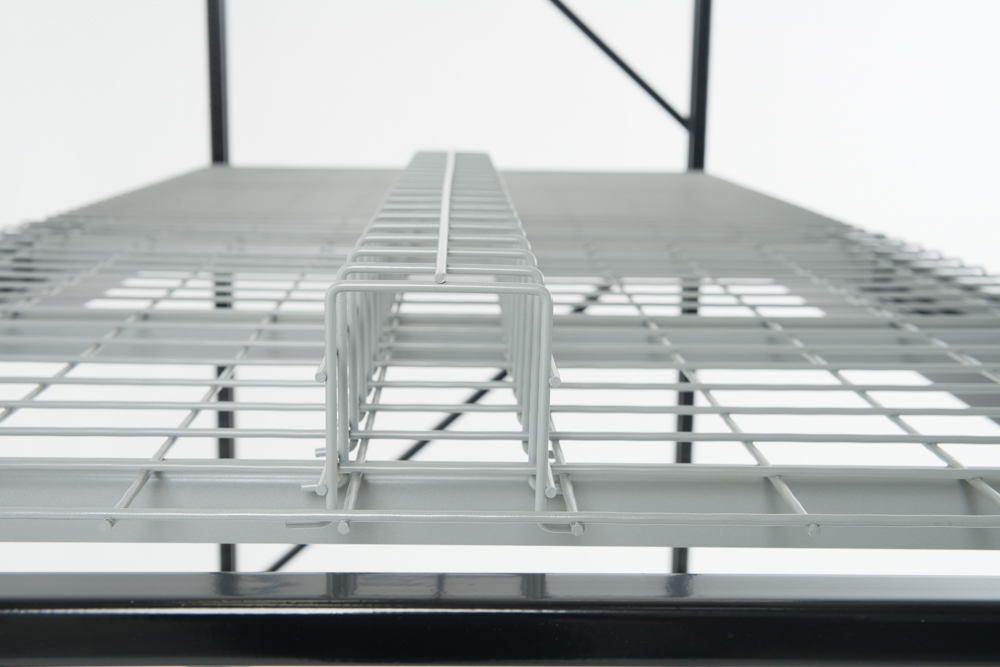

Center Flues for Sprinkler Systems

Some racking solutions include sprinkler systems that provide fire safety to the racking system. It is important to make sure that inventory is not in the way of these systems as they can keep the sprinkler from getting water to the entire rack solution should a fire occur.

This is where having a proper carton stop is beneficial. Nashville Wire manufactures a carton stop developed to tension fit into the wire decking solution in order to create the required flue in the center of the level.

This flue provides enough space for the sprinkler to reach other areas of the racking solution without being obstructed or damaged due to materials being in the way.

Creating Storage Cubbies

For some applications, facility managers require storage for many different SKU’s in order to properly organize all the different materials they have. This can be done within a racking solution using dividers on the wire decking.

Nashville Wire’s Kwik Klip™ and hanging dividers offer this separation in order to section off areas of the racking for different SKU’s.

Kwik Klip™ makes use of a rounded frame that quickly and easily clips onto the wire decking allowing for easy installation and relocation should SKU areas change.

Hanging dividers hang from above wire decking creating storage bin areas below and are also easy to install and relocate!

Adding it All Together

All these creative options can be implemented together as well! This allows you to create an all-encompassing wire decking solution that increases efficiency, safety, security, and separation for your rack.

Once you have an idea of what you want your storage solution to consist of you can use Nashville Wire products to outfit the entire operation and give you the ability to quickly implement decking or relocate it quickly should storage areas change in the future!

Of course, if you are in need of someone to help get the creative juices flowing give Bode a call and one of our highly experienced sales representatives can come out to take a look at your application and offer their opinion on what creative decking options you should implement!